Boiler Metal-Fach GRAND PELLET 150 kW

GRAND PELLLET is adapted for efficient combustion of different quality biomass, and self-cleaning burner together with an automatic self-cleaning boiler exchanger system, which significantly reduces frequency of boiler cleaning.

Fuel: Pellet

Pellet is an ecological fuel that is produced by pressing wood waste such as sawdust or shavings. It is fully natural, thus burning does not produce harmful compounds into atmosphere.

Internet module ecoNET

Communication module cooperating with PLATINUM controller enables servicing, operation and management of boiler using a computer, tablet or cell phone via an intuitive website www.econet24.com. Thanks to built-in web server in ecoNET module, it is possible to remotely manage boiler operation in local network without access to Internet.

Self-cleaning

Burner is equipped with a mechanism that cleans itself from ash on its own and regularly, so there is no need to clean it.

Exhaust fan as standard

This solution gives us a greater possibility of configuration, which helps to optimize it.

Automatic feeder

The controller, on the basis of measurements from combustion sensors, recalculates the fuel demand and regulates its appropriate amount. Thanks to this, the combustion process is economical, ecological and does not require any additional user service.

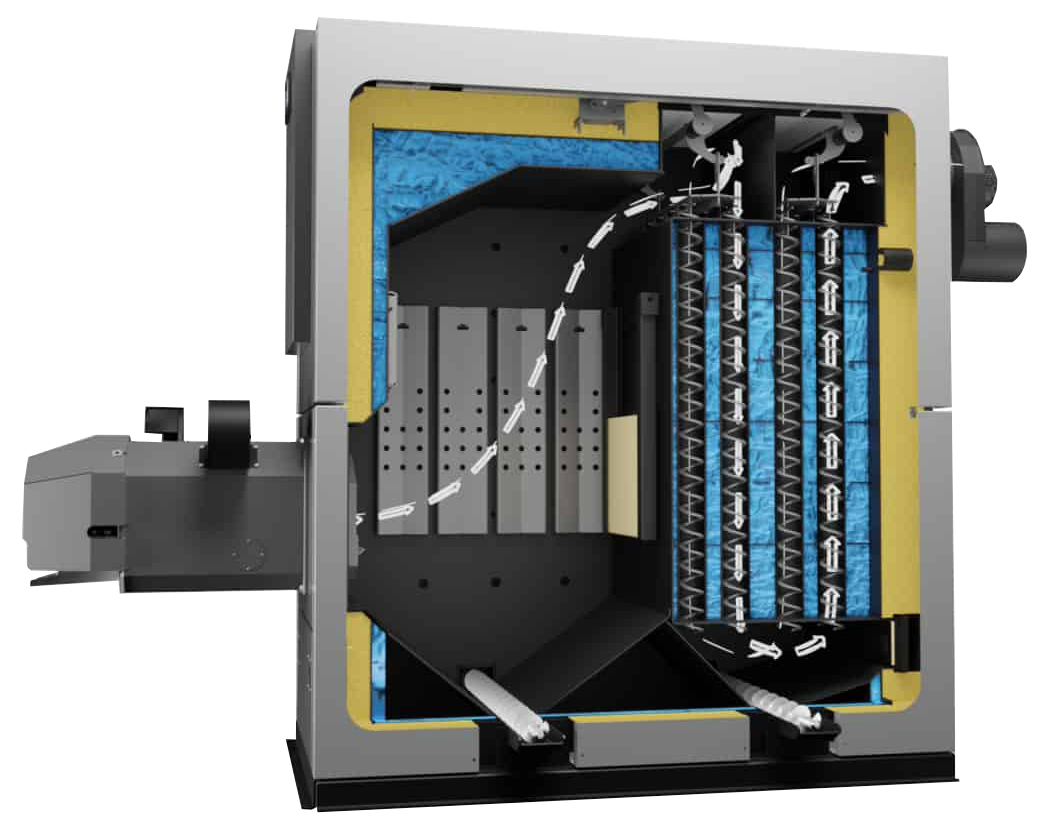

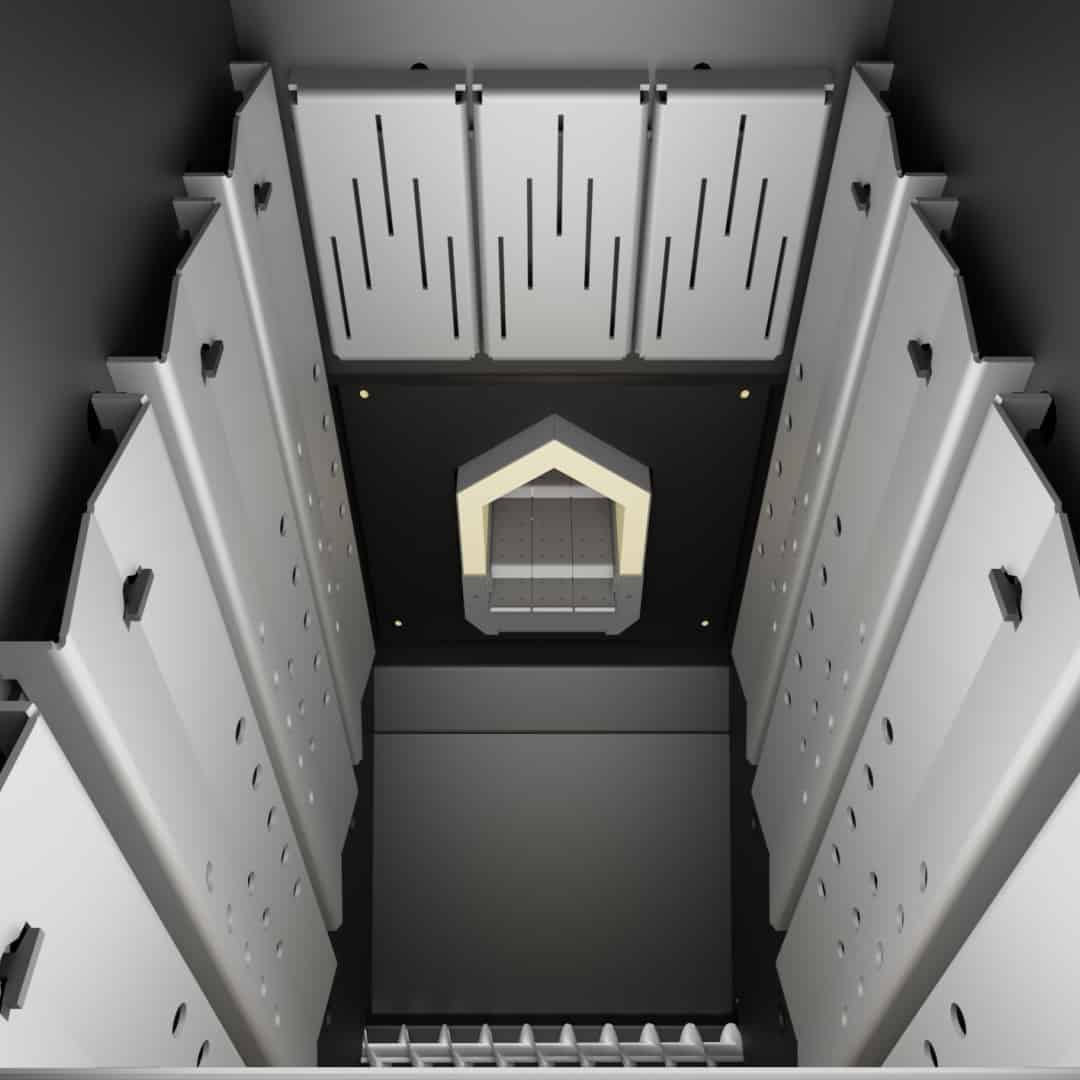

Vertical convection channels

Construction of boiler exchanger ensures a high heat reception from furnace. Steel screens and swirls have been installed in body, which delay air outlet, which results in collection of more heat by central heating circuit.

Steel screens

Steel screens raise temperature in tcombustion chamber and stop particles floating over fireplace, burning them. As a result, thermal efficiency of furnace is increased and outgoing flue gases are much cleaner.

Mechanized self-cleaning system of exchanger

Thanks to exhaust gas swirlers that are connected to geared motor, boiler is able to self-clean unwanted soot deposited in convection channels. We can configure cleaning frequency via controller display.

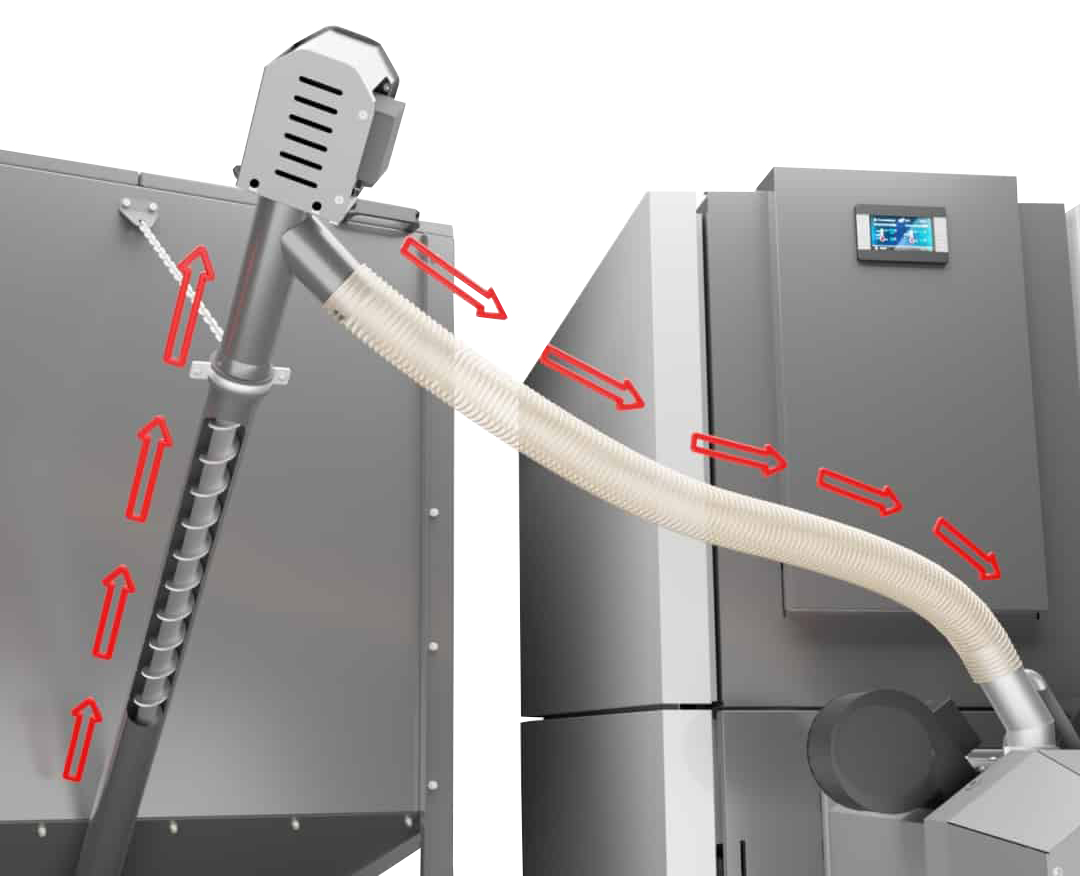

A screw system for removing ash from the inside of the boiler

Augers have been used for boiler, which are responsible for removing ash from boiler to outside. Ash is transported to special sealed containers. This ensures that boiler maintains right parameters.

Ash collection containers

Combustion residues are discharged into specially designed containers placed on the side of boiler. Containers are tightly fixed to boiler structure, preventing dust from getting outside. It is enough to empty containers once every few weeks to keep inside of boiler clean.

Advantages of boiler:

- Self-cleaning boiler exchanger

- Screw system for ash removal from boiler

- Automatic ceramic pellet lighter

- Self-cleaning burner

- Two automatic ceramic pellet igniters in a 75 kW boiler

- One automatic ceramic pellet igniter in a 50 kW boiler

- Vertical convection channels

- Automatic feeder

- Large pellet container

- Convection channel mounted swirls

- End protection system placed in boiler door

- Mechanized self-cleaning system of exchanger

- Screw system for ash removal from inside boiler

- Ash collection containers

- PLATINUM controller

- Room thermostat

- Internet module

- Certificate 5 Class, Eco Design

- Output of flue pipe at back

- Fuzzy Logic & PID

- Weather control

- Winter/summer operating mode

- RTC clock with weekly programmer

Parameters

| Parameters | SI unit | Boiler Model | |||

| GRAND PELLET 50 | GRAND PELLET 75 | GRAND PELLET 100 | GRAND PELLET 150 | ||

| Nominal thermal power | [kW] | 50 | 75 | 100 | 34 |

| Boiler power range | [m2] | 15 - 50 | 22.5 - 75 | 30 - 100 | 45 - 150 |

| Heating area | [m2] | 225 - 750 | 337.5 - 1125 | 450 - 1500 | 675 - 2250 |

| Water capacity | [L] | 245 | 245 | 360 | 360 |

| Maximum operating pressure | [bar] | 3 | |||

| Maximum operating temperature | [°C] | 80 | |||

| Test pressure | [bar] | 4.5 | |||

| Fuel tank capacity | [L] | 1000 | |||

| Fuel tank capacity | [kg] | 600 | |||

| Fuel | [-] | pellet Φ6-8mm | |||

| Electrical connection | [-] | 4A; ~230V; 50Hz | 3.2A; ~230V; 50Hz | 4.5A; ~230V; 50Hz | |

| Electrical power consumption | [W] | 300 | 300 | 320 | 320 |

| Temperature controller setting range | [°C] | 60-80 (every 1°C) | |||

| Required chimney draft | [Pa] | 33 | 38 | 40 | 44 |

| Boiler weight | [kg] | 880 | 880 | 1095 | 1125 |

| Ecodesign | [-] | + | |||

| Boiler class | [-] | 5 | |||

| Energy efficiency class | [-] | A+ | |||

| Seasonal particulate matter emission | [mg/m3] | 13.87 | 16.01 | 13.14 | 16.82 |

| Efficiency for nominal power | [%] | 92.82 | 92.75 | 92.83 | 92.78 |

| Nominal particulate matter emission | [mg/m3] | 10.04 | 12.15 | 10.14 | 11.64 |

| Efficiency for minimum power | [%] | 93.09 | 92.93 | 92.66 | 92.93 |

| Minimum particulate matter emission | [mg/m3] | 14.54 | 16.69 | 13.67 | 17.73 |

Dimensions

| Type | GRAND PELLET 50 | GRAND PELLET 75 | GRAND PELLET 100 | GRAND PELLET 150 |

| A | 2429 | |||

| B1 | 1255 | |||

| B1' | 815 | |||

| B2 | 1111 | |||

| C1 | 1475 | 1715 | ||

| C2 | 1636 | |||

| D1 | 2190 | 2500 | 2600 | |

| D2 | 1450 | 1600 | ||

| E | 1890 | 2130 | 2230 | |

| F1 | 1015 | 1345 | ||

| F2 | 970 | 1250 | ||

| F3 | 1000 | 1140 | 1240 | |

| F4 | 145 | |||

| G1 | 180 | 185 | ||

| G2 | 1 1/2 | |||

| G3 | 1 1/2 | |||

| G4 | 3/4 | |||

| H | - | |||

Product specification

| Power output | 150 kW |

| Boiler class (303-5:2012) | 5 |

| Ecodesign | + |

| Size of heated surface | 675 - 2250 m² |

| Water capacity | 360 L |

| Max. water temperature | 80 °C |

| Max working pressure | 3 bar |

| Silo volume | 1000 dm³ |

| Power supply | 4,5A , 50Hz , ~230V |

| Warranty | 5 |

Opinions

ℹ️ Viewed reviews are moderated. We do not verify that they come from customers who have purchased the product.